Mhs - Material Handling Supply Inc. Things To Know Before You Buy

Table of ContentsThe Single Strategy To Use For Mhs - Material Handling Supply Inc.Mhs - Material Handling Supply Inc. Fundamentals ExplainedFacts About Mhs - Material Handling Supply Inc. UncoveredMhs - Material Handling Supply Inc. Things To Know Before You Get This5 Easy Facts About Mhs - Material Handling Supply Inc. ExplainedSome Of Mhs - Material Handling Supply Inc.A Biased View of Mhs - Material Handling Supply Inc.

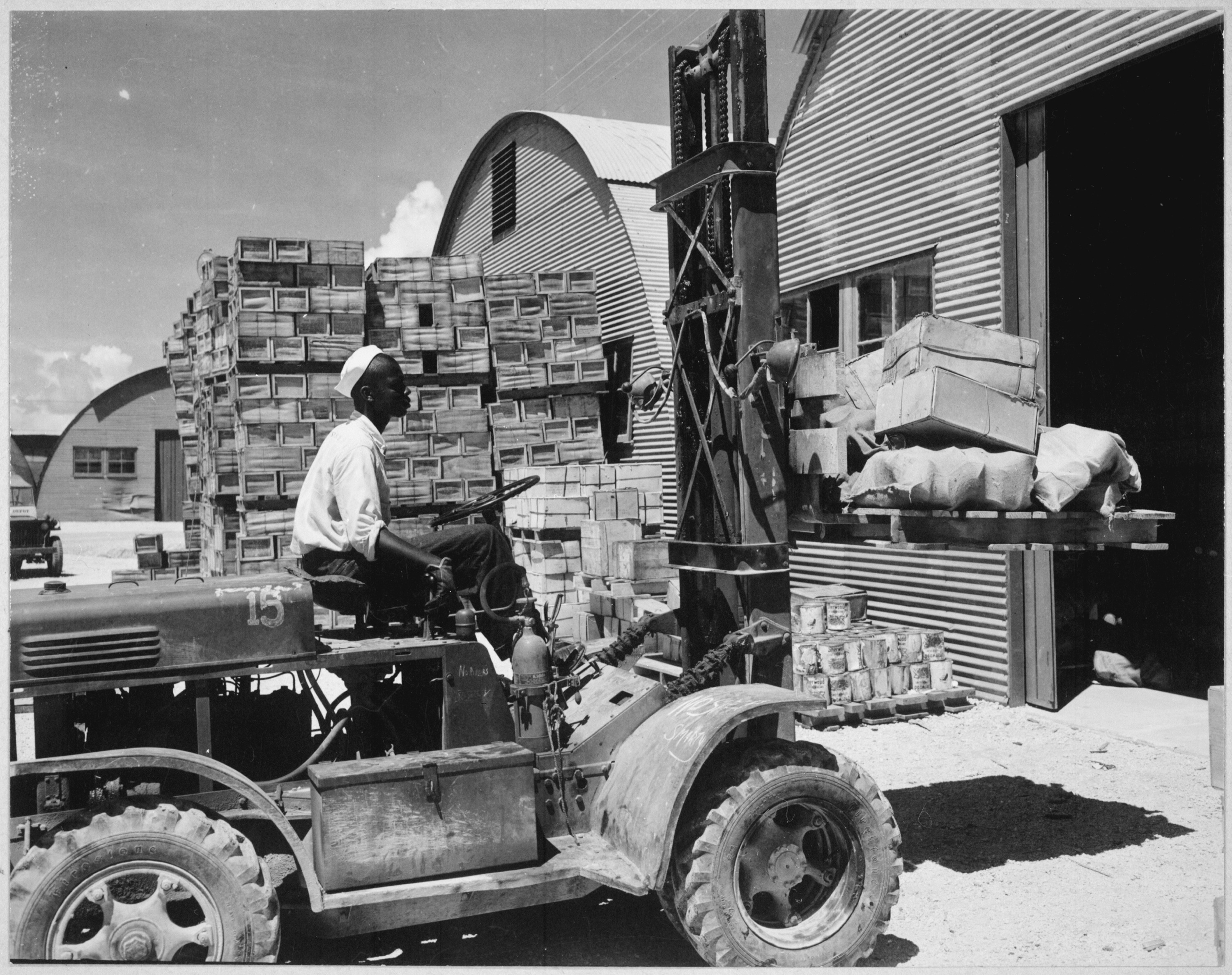

Generally, this tools is usually utilized in an industrial setting to relocate items and items. There are 4 major types of product handling tools that help storage facilities and factories move and store products, which are: Transportation Devices Positioning Devices Unit Load Development Devices Storage Equipment Industrial vehicles, like forklifts, fall under product handling devices and are utilized to move hefty products safely.

Compared to standing utilizing a stand-up biker. Specifically when raising and lowering. Harsh surface forklifts are developed to function at building sites or various other locations on irregular surface areas.

How Mhs - Material Handling Supply Inc. can Save You Time, Stress, and Money.

When it comes to product handling forklifts, telehandlers can get to the highest possible elevations and carry the most weight - forklift rental. With a slim aisle forklift, you can do more with less space. Narrow aisle forklift trucks are developed to be used in aisles that gauge less than 10 feet by 12 feet

An is a sort of product handling devices utilized to choose and provide goods from storage for orders. Furthermore, order pickers let drivers quickly and rapidly pick items from containers of various SKUs for order gratification. are the most basic type of forklift and are made use of to move pallets in warehouses.

An additionally known as a, is a mechanized forklift made use of to aid building employees in getting to high elevations for work and jobs. There are a number of different types of airborne lifts that are developed for various construction jobs which we've provided below.

What Does Mhs - Material Handling Supply Inc. Do?

Utilizing them, business employees can reach raised elevations or hard-to-reach locations pleasantly. Since there are several kinds of boom lifts, it's important to find out the different attributes and features of each.

These vehicles raise people right into the air securely in order to perform jobs. are aerial lifts designed to function in extremely tight and constrained areas. The combination of high lifts, reach, and adaptability of these systems makes them a safe solution. These upright pole lifts feature wheels, hence making it easy to relocate and carry the lightweight maker.

10 Easy Facts About Mhs - Material Handling Supply Inc. Shown

It is being thoroughly used throughout the industry for moving materials and products. Forklift is composed of selection of components required to deal with the job properly. From Vehicle Structure, source of power to counterweight are vital for the forklift to work successfully. Vehicle Structure is one of the most crucial component which forms the base of the device.

The Weight is a cast iron weight connected to the back component of the forklift. The objective of the weight is to respond to equilibrium the load that is being raised. On Electric Forklift, Counterweight is taken care of to the lead-acid battery. The forklift's power resource includes an internal burning engine.

The carriage offers as the base to the forklift. The Pole is a vertical part that lifts up and presses down the tons.

The Greatest Guide To Mhs - Material Handling Supply Inc.

Air gets allured via the base of the cylinder that permits gasses to go into without dripping them out. The volume of gas in the cyndrical tube increases the pressure inside it - https://www.blogtalkradio.com/mhsinc30677. The pressure applied to the area of the piston head generates an upward force. This force causes the piston to go up, boosting the More about the author volume of the gas and decreasing the stress.

The Driver presses the deal with in an ahead instructions, signifying the forklift to pump excess air to the cyndrical tubes. The operator pulls the take care of in backwards instructions that signifies an unique valve to release gas from cylinders. The hydraulic pistons are attached to both primary vertical frameworks called "poles".

When the hydraulic pistons press the masts in upward instructions, the equipments on the poles is pressed against the roller chains. It occurs because the one side of the chain is taken care of to the stationary frame of the forklift, and the only means whereby poles can move upward is when gears turn in clockwise direction and pull the forks expenses.

Mhs - Material Handling Supply Inc. Fundamentals Explained

There are two pairs of additional hydraulic cylinders attached to the base of the poles. Once the Tilt Handle is relocated ahead direction, the air automatically fills the chamber (forklift rental). The rise in stress suffices to press the head of the piston and let the poles go away from the lorry's body

Fascination About Mhs - Material Handling Supply Inc.

When the pistons are pressed forward, the masts are pushed back to the automobile. Forklifts have completely changed the storage and delivery sectors. Forklifts were very first created throughout early component of the 20th century and currently had actually become an essential part of the contemporary commercial globe. Forklifts are called after their fork-like prongs that raise up the tons.